PROJECT SUMMARY

A leading breakfast cereal brand, in partnership with ESKO Australia Pty Ltd and MESPIC srl, has expanded its product line to include spouted pouch snacks. This collaboration focused on revamping the packaging process, which initially involved extensive manual labor for handling and packing spouted pouches. The goal was to streamline and standardise this process for efficiency and scalability.

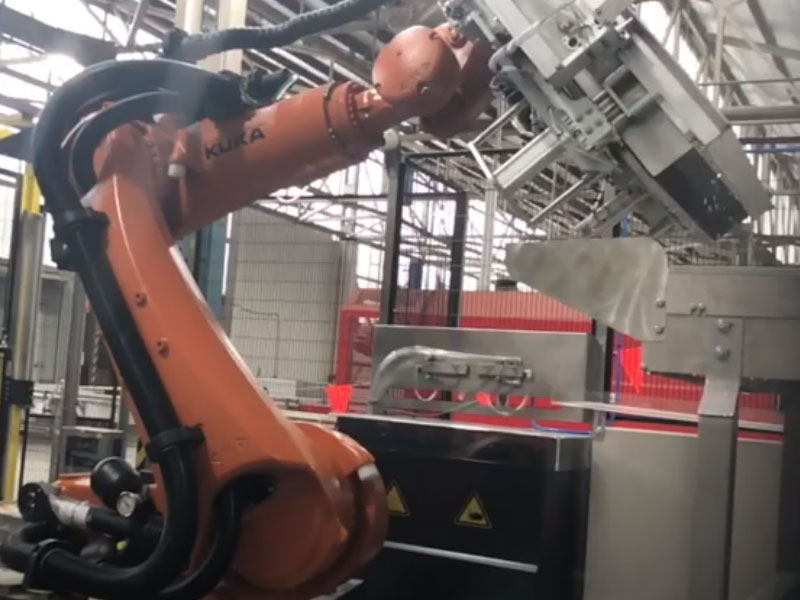

The brand and its partners developed an automated solution to enhance production. This new system focused on reducing packaging material costs, maximising pallet utilisation, and increasing flexibility for various product flavours. It employed advanced sorting, aligning, and packaging technologies, including vibrating systems, vision confirmation, and robot-assisted placement, significantly improving the efficiency of the packaging process.

This successful automation project, underpinned by a strong partnership and comprehensive project management, resulted in a more efficient operation, allowing for a 15% increase in product capacity per pallet. This development has greatly enhanced the brand’s production flexibility, enabling it to meet growing market demands more effectively.

KEY BENEFITS

PHOTO GALLERY

FURTHER INFORMATION

David Gearing T: +61 3 9464 5611

david.gearing@eskoaust.com