PROJECT SUMMARY

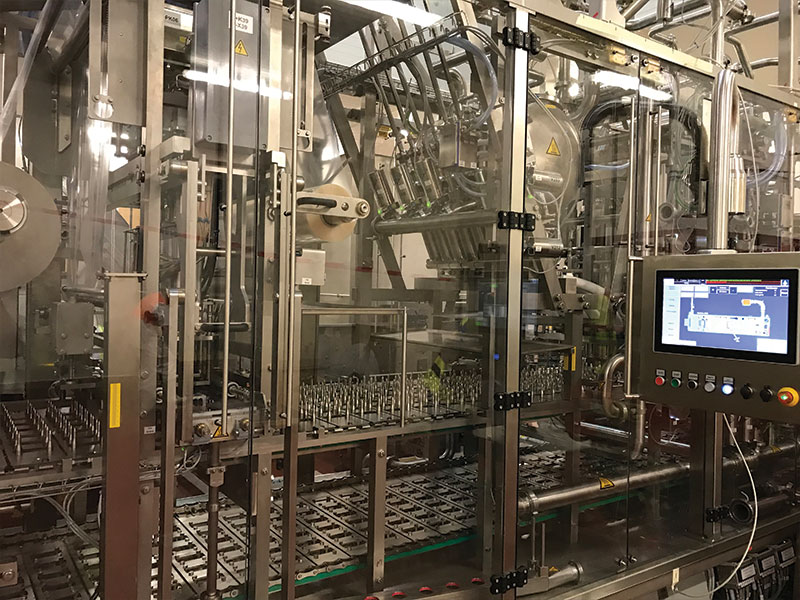

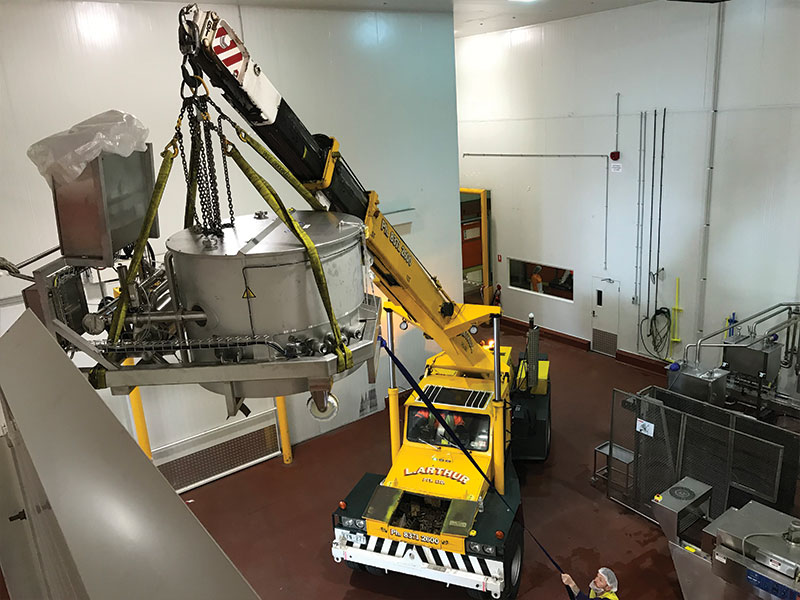

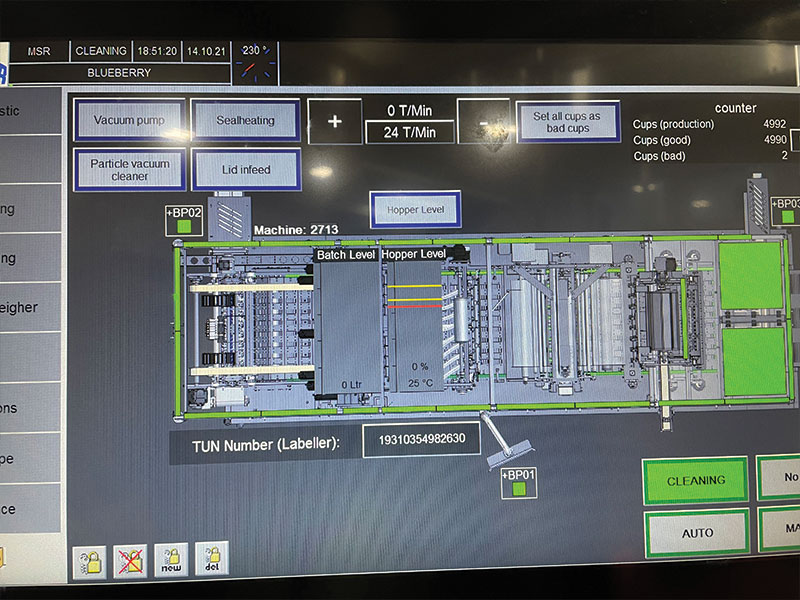

ESKO installed a Waldner Dosomat filling and packaging line for a leading Australian Dairy company, revolutionising their yogurt production. This advanced machine efficiently cleans and fills each pot using a precision drip-less nozzle, followed by a secure sealing process. It also includes a critical seal integrity check for each pot, ensuring top-notch product quality and safety.

The machine’s standout feature is its ability to weigh each pot individually, adjusting the fill dosage to minimise waste and maximise accuracy. It is equipped to reject any underweight pots, maintaining consistent quality automatically. Following the filling process, ESKO has integrated a Langguth labelling machine that expertly applies both top and side labels, enhancing the product’s appearance and providing essential information.

Completing the setup, the Mespic AIO (All-In-One) packer, installed by ESKO, efficiently handles multiple packaging tasks within a single compact footprint. This includes forming the box, inserting the product using advanced technology, and sealing it with Nordson hotmelt glue. The installation also includes a Mespic palletising system with two bays, enabling continuous, non-stop production and significantly boosting efficiency and throughput in the yogurt packaging line.

KEY BENEFITS

PHOTO GALLERY

FURTHER INFORMATION

David Gearing T: +61 3 9464 5611

david.gearing@eskoaust.com