EMS Conveyors

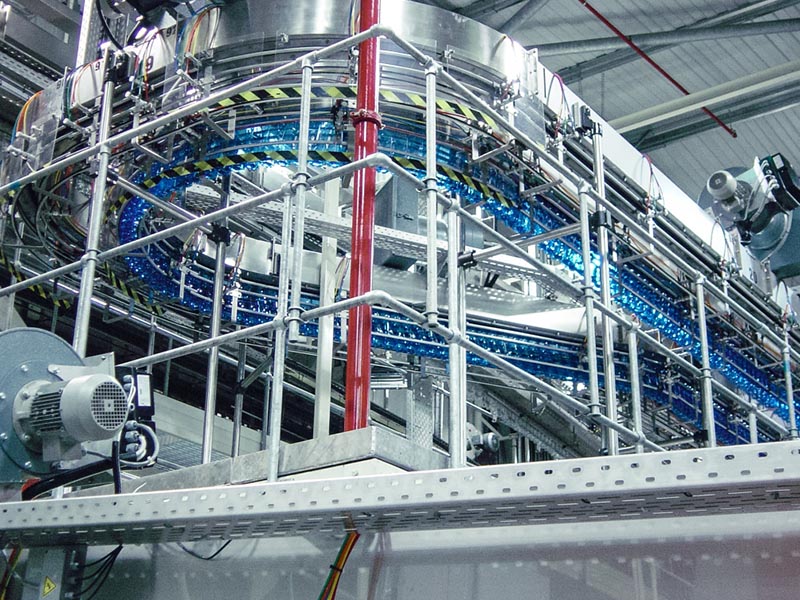

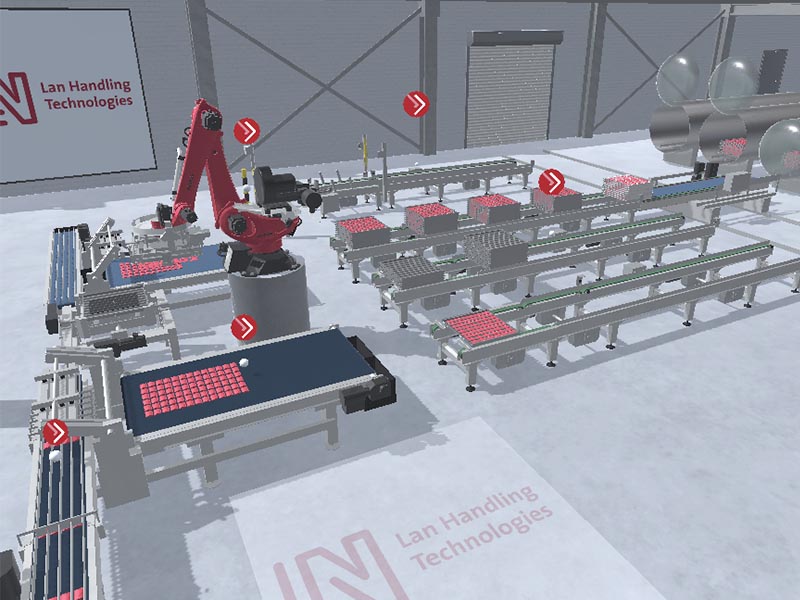

EMS provides a complete engineering solution for the construction of conveying lines for PET, aluminium and tinplate cans, packaged glass containers and HDPE containers. EMS’s conveying solutions adopt different conveying systems to guarantee the optimal solution based on the type of product processed, with production capacities ranging from 100 to 2,000 containers per minute.

For more information submit a sales enquiry or call +61 3 9464 5611.

Description

KEY APPLICATIONS

- PET & HDPE: Air or vacuum conveying systems for empty PET and HDPE containers with capacity ranging from 100 to 1500 containers per minute.

- FULL GLASS: Conveying systems for empty or full glass containers (jars and bottles) with a production capacity ranging from 100 to 1500 containers per minute.

- TINPLATE CANS: Conveying systems for empty and full tinplate cans with a production capacity ranging from 100 to 2000 containers per minute.

- ALUMINUM CANS: Conveying systems for empty and full aluminium cans with a production capacity ranging from 100 to 2000 containers per minute.

- BRICK: Conveying systems with a production capacity ranging from 100 to 500 containers per minute.

- PLASTIC POUCHES: Conveying systems with a production capacity ranging from 50 to 500 containers per minute.

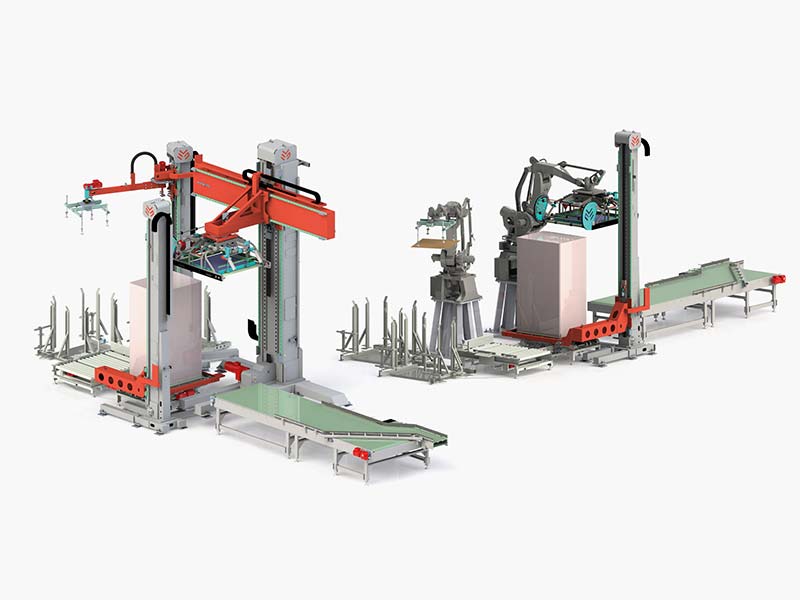

- CONTAINERS PACKAGED IN BUNDLES, CARTONS, CRATES AND TRAYS: Conveying systems for empty and full containers with a production capacity ranging from 10 to 300 containers per minute.

"*" indicates required fields